Blew My Mind! - This Is the Future of Cod Fishing! Dion Rydell, Mustad Autline Coastal system, Newfoundland, Canada

When we first started fishing with the Mustad Autoline Coastal system about 6–7 years ago, it honestly blew my mind how smooth and efficient it was. For me, it completely changed the way we fish for cod — and now I wouldn’t want to do it any other way,” says Dion Randell, owner and skipper of the TNT Voyager, a 65ft vessel fishing cod out of Newfoundland, Canada.

Fishing with around 13,000 hooks onboard, the results have been impressive. On one 3-day trip with a crew of six, they landed 65,000 pounds of gutted cod — a catch they’re very proud of.

“We were one of the first companies to invest in an Autoline system after the cod returned to our waters. Besides cod, we also fish for crab, shrimp, and turbot. The system has really become a key part of our operation.”

Now Dion and his son are considering investing in another Autoline system for their smaller vessel, the Buds Legacy.

“This is the future of cod fishing for me,” Dion says.

Dion recently visited Mustad Autoline in Iceland and toured the factory in Norway to learn more about the technology and gain new ideas to keep developing his business.

Mustad Autoline is represented by Kerwin Wellon in St. John’s, Newfoundland, Canada.

There’s no doubt! - the electric coastal baiting machine is ten times better than the hydraulic version.” - new statement from the skipper and owner Ólafur Einarsson, Øksnes, Norway – Autoline vessel Einar

"We have now operated the electric baiting machine from Mustad Autoline for one year (Number of hooks through the machine; 3 740 178). During this period, we have only replaced four knives. The reason was that the motor initially delivered too much torque (Nm), which caused the knives to break. The motor torque is now adjusted to the correct leval.

Our overall experience has been very positive. There is no question that Mustad has developed a machine that is significantly improved — at least ten times better than the hydraulic version.

E-Line AutoBaiter – Mustad Autoline

https://vimeo.com/1136882479

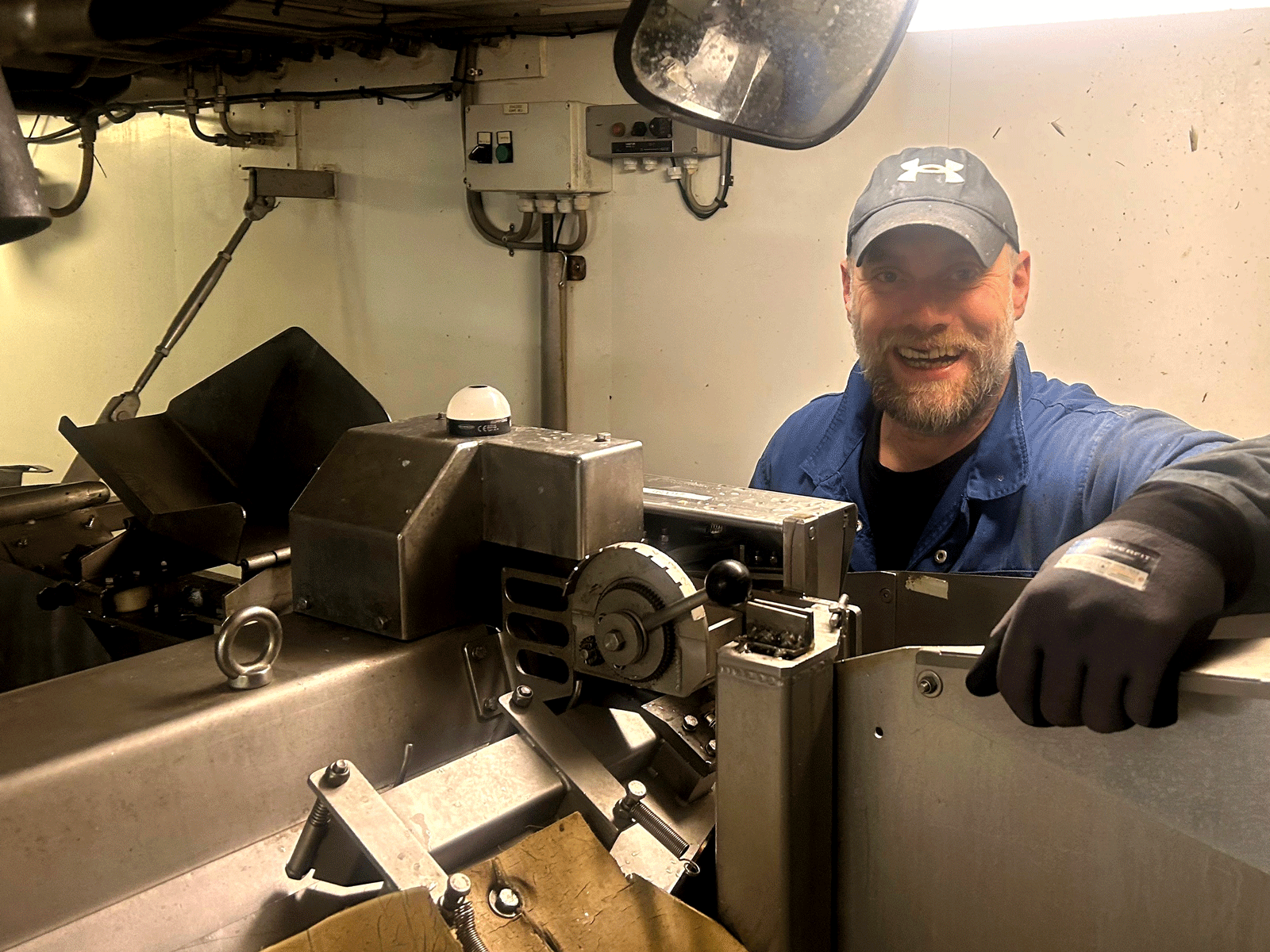

Mustad Autoline E-Line system; Greetings from Chief Engineer Sebastian Gustafsson at M/S Fiskenes

We are keeping more of the larger fish on the line during hauling

The new machine at Mustad Autoline delivers impact far beyond the company’s own factory.

Fv. Anders Frisinger, Thor Anders Vesterås, Tina Elisabeth Arvidson, Maksymilian Nasiadek, Emma Østerbø, Lasse Rindahl og Hans Mustad

The new machine is a combined turning and milling machine, built as a heavy-duty lathe with two spindles and a robust milling unit. It has five axes and two chucks, allowing the workpiece to be machined from multiple sides in a single setup.

“In practice, this means you clamp the workpiece once, and the machine does the rest. The first chuck handles the rough machining. then the second chuck takes over and completes the work. The machine is running almost continuously,” explains plant manager Thor Anders Vesterås.

For those who are not “machine people,” the main point is simple: less manual work, fewer operations, higher precision, and shorter lead times.

Read the whole article: Ny maskin hos Mustad Autoline gir effekt langt utover egen fabrikk – MTNC

E-Line Coastal system; Feedback from skipper and owner Ólafur Einarsson, Øksnes, Norway – Autoline vessel Einar (25,000 hooks)

Skipper and vessel owner Ólafur Einarsson from Øksnes shares his experience after upgrading his autoline vessel Einar with the E-Line Coastal system.

“We switched to the E-Line PLS control system, hook separator, and baiting machine about a year ago.

Our experience has been very positive. The system runs smoothly and quietly, without the need for hydraulics or oil, and with lower maintenance costs compared to the old hydraulic system.

The ability to set the exact bait size makes it possible to optimize operations and reduce bait consumption, as every hook is baited precisely and consistently each time.

Also, we can set with more speed than before, and with much better baiting when the boat speeds up and "runs with the big waves".

Previously, with the hydraulic system, we set at 5.5 knots, but now with the electric machine we set at 6.5–7 knots and achieve 98% baiting.

We have also received excellent follow-up and support from the Mustad Autoline service team throughout the year.

I am very satisfied and can truly recommend converting to electric machines and the new control system – this is the future!”

E-Line AutoBaiter – Mustad Autoline

https://vimeo.com/1136882479

Next stop North Atlantic Fish & Workboat Show, Canada November 14 - 15

Next stop Pacific Marine Expo, Seattle November 20 - 22

The fishing vessels Panituaq and Nanuvik: Greenland, fishing with Mustad Autoline Handy Mag system

Ernst Lund, owner of two vessels fishing for cod and halibut with Mustad Autoline system since 2018. "Mustad Autoline makes our work easier and more efficient. Mustad Autoline is quality - the best og the best!" he says.

The vessels Panituaq and Nanuvik both equiped with Mustad Autoline HandyMag systems fishing outside of Upernavik in Greenland with a crew of 4 each vessel.