ALBIUS, SAPMER (FR) fishing with E-Line for toothfish since 2022

We have been working with the all-electric longline fishing system for 2 years now.

After these months of operation we have not had any major problems. Working on deep waters (2000 meters) we asked Mustad for adjustments to the reactivity of the hauler. It is obvious that the electric control is precise and sensitive. The different settings make it possible to optimize the behavior of the vessel in relation to waves and the speed of the line retrieval.

For sailors, captains and chief engineers, this generation of electrical system is well thought out. The baiting process is the greatest advantage. We can use multiple bait sizes and change hook sizes very easily.

I also want to commend the Mustad after-sales service technician team. They are professional, attentive, and a pleasure to work with!

Patrice Boitel, Technical Manager SAPMER

Patrice Boitel, Technical Manager

M/S O. HUSBY Freezer longliner (NO) - fishing with Mustad Autoline DeepSea System

My colleagues and I at O. Husby Fishing Company couldn’t be more satisfied with the Mustad system we have on board, along with the excellent service and follow-up.

Our engineers praise the availability of spare parts, the swift processing, and the high quality of the goods delivered by Mustad Autoline.

Not to mention, the staff at Mustad are incredibly friendly, accommodating, and easy to work with.

We have been a loyal customer of Mustad Autoline for 40 years, and we fully intend to continue that partnership in the years to come.

Skipper, M/S O. Husby

Ole Anton Husby

LIVE ELISE, - fishing with Mustad Autoline Coastal full time

- Why did you choose Autoline and Mustad Autoline?

I chose Mustad Autoline because it was the first option that came to mind when I started planning for an autoline system. I know it has been tested and proven in every possible way. At the same time, I know that many boats use their systems, making it easier to inquire about challenges and operational questions. We chose autoline to streamline operations, reduce costs, and make the crew’s workdays easier. - Are you satisfied with the system, and does it meet your expectations?

I am very satisfied with the system, and in my opinion, it exceeds expectations. Here, I must highlight the excellent cooperation with both the salespeople and the service staff. - What impresses you the most about the Autoline system on board?

It’s impressive how user-friendly the autoline system is in operation. The solutions for performing the tasks are well thought out, and it’s easy to keep clean. What I expected to be a major challenge—the baiting machine, its maintenance, and upkeep—has turned out to be worry-free. It’s very straightforward to keep everything running smoothly, and if something does come up, I know the service technician is just a phone call away. - You’re building a new boat now; was it an easy decision to choose autoline for this boat as well?

Yes, absolutely! We are taking the experiences from the old boat and improving the setup on board to increase efficiency with more storage capacity and a larger number of hooks. - Would you make the same choice again compared to manual baiting or using nets, etc.?

Yes, absolutely! Manual baiting works very well if there are only a few crew members on the boat and is ideal for that scenario. But in my opinion, if you have more than 2–3 crew members on small boats, an autoline system is a must. I would absolutely choose Mustad Autoline again!

Robert Brun, Stø in Norway 2021 – Coastal fisherman 😊 Vessel: Live Elise, 10,99 m

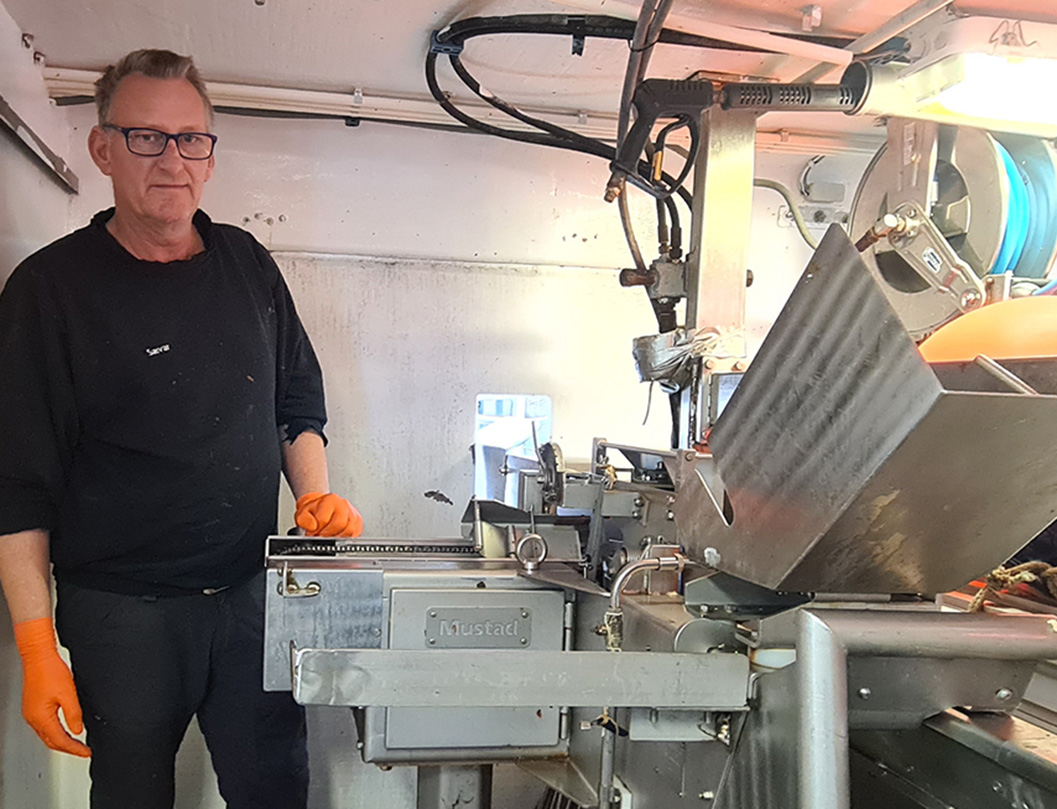

NORLINER, fishing with Mustad Autoline Coastal System since 2012

“The fishing boat «Norliner» (N-54-Ø), based in Øksnes municipality in Nordland in Norway, is a 10-meter vessel that has been operating with Mustad Autoline coastal system since 2012. For us, it is much more flexible and easier to use Autoline, and we will never go back to using traditional longlines. If it ever became an issue, I might as well quit fishing, says Sævar Gudjonsson. We handle most of the maintenance ourselves, which also makes our daily operations easier.

I got involved in the boat’s operation in 2014, and in 2016 we bought the Norliner.

Sævar Gudjonsson

DUKAT, Mustad Autoline Coastal - The installation of the MA HV 50 has improved my workday significantly

“Æ har no drevet med linefiske heile livet, og etter at æ fikk installert Mustad Autoline HV-50 på båten for fem år sia, så blei alt bra mykkje likar,” sier Arnfinn Mikalsen. «Arbeidsstillinga om bord blei mykkje bedre, og det blei merkbart mindre støy»

“I installed the Mustad Autoline HV-50 hauling unit on my boat five years ago, and since then, everything has improved significantly,” says Arnfinn Mikalsen. The working conditions on board became much more comfortable, and the noise levels were noticeably reduced.

Arnfinn has enjoyed consistent support from Mustad over the years and has maintained a great dialogue with the company. He was even involved in the development and testing phases of the HV-50 hauler. He describes it as solid and user-friendly, although perhaps a bit long for the smallest coastal vessels—a suggestion for future development.

Arnfinn Jarl Mikalsen, Båtsfjord – Coastal fisherman 😊 Vessel: Dukat, 35 feet

LEINEBRIS, Mustad Autoline - A trusted partner for the future of line fishing operations

Mustad Autoline’s E-Line system was the natural choice for this mission. One of the key reasons we trust Mustad Autoline is their proven experience over many years. Their systems are tried and tested over a long period, and we’ve consistently seen the results. In addition, Mustad’s strong customer service is a major asset—whenever we need support, we know we can count on quick and reliable responses. Their accessibility and willingness to listen have built a trust that is invaluable in our operations.

On the technical side, their innovative technology, like the E-Line’s dynamic tension control, ensures consistent line speed and fewer lost fish. For us, Mustad Autoline represents not just cutting-edge equipment but a partner we can rely on for the future of our line fishing operations.

Paul Harald Leinebø, owner, and Åge Uran, owner and chairman of AS Leinebris, are on schedule building their state-of-the-art vessel at Tersan Shipyard in Turkey. Equipped with fully electric deck machinery, including Mustad Autoline’s new all-electric autoline system and net hauler, the new vessel is designed to maximize energy efficiency. “We want to fish for the future and take care of the resources we have in the best possible way,” says Uran. “To do that, we need to think new and build new.” This commitment to innovation and sustainability reflects the company’s forward-thinking approach, aiming to make the most of all the energy generated on board while ensuring the highest standards of efficiency in their fishing operations.

Åge Uran October 2024

LORAN, Ståle Dyb "We get Bigger Catches and Cuts Fuel Costs with Mustad Autoline E-Line System"

Ståle Dyb, skipper and owner of the Norwegian autoliner Loran, has experienced remarkable benefits since switching to the Mustad Autoline E-Line system. According to Dyb, “The result is more fish.” The innovative design of the E-Line system’s dynamic tensioning keeps the line speed consistent underwater, reducing the likelihood of fish shaking off the hook. “When the vessel goes up on a wave,” Dyb explains, “the line almost stops, and when the vessel goes down, it picks up again.” This steady control minimizes slack and maximizes catch rates.

In addition to improving his catch, Ståle Dyb has also seen fuel consumption drop significantly, calculating a savings of about 20 tons of fuel per year (approximately 5,633 gallons). This reduction in power consumption is a direct result of the E-Line’s electric powersupply, which is much more efficient than traditional hydraulic systems.

The comfort of his crew has also increased thanks to the system’s reduced noise and vibration. “The electric motor runs without noise,” says Dyb. “It is much more comfortable to work in less noise, and the crew confirms that. That was their first reaction to the new unit.” With lower energy consumption and a quieter, more efficient operation, the E-Line system has transformed both the working environment on board Loran and the overall operational efficiency.

Fisherman Even Hauge Sees Huge Success with Loppa 100: "We've Processed 30-50 Tons Weekly – Couldn't Do It Without the Machine!"

«We’ve been running 30-50 tons through the machine each week. Extremely satisfied! Without the machine, they might as well stay on land… says Even Hauge. He also has a lot of expertise on what’s important when it comes to maintenance and operation of the machine. They welcome visits on board if anyone wants to see and hear about their experiences.»

«Hauge Junior» had its first machine, Loppa 100, installed in the fall of 2018 on the old «Hauge Junior.» The machine was used extensively on board, and the experience was so positive that he ordered a new machine for his new boat in the spring of 2020. From January to August the same year, the machine has headed and gutted over 1,200 tons!

Five Years On, Hitra Fisherman Hallgeir Breivik Praises HAVFRONT LOPPA 100: "I'm extremely satisfied"

«The machine has made the work on board much easier. We’re not getting any younger. The shoulder blades are very vulnerable, and the head cutting is the worst. Before, I was exhausted after a day out at sea, now I don’t feel anything. Before and after Loppa, it’s like night and day,» says Breivik.

After receiving good advice from one of the crew members on the «Mats-Erik,» the first boat to use Loppa, Hallgeir Brevik made the decision: Loppa was going on his 36-foot boat «Einevikbuen.» He hasn’t regretted that decision.

«You can’t get more for your money than this. I bring in more fish since it’s much faster to gut them, and at the same time, the strain is reduced,» says Breivik.

He is also impressed with the follow-up he has received after the investment, but most adjustments are easy to make, allowing fishermen to maintain Loppa themselves. «I handle a lot myself, and the machine is easy to maintain,» says Breivik.

HAVFRONT LOPPA 100 - made by Mustad Autoline

With great respect for the solid work that has gone into the development of Havfront products, we would like to inform you that Mustad Autoline has now taken over and continues to produce these high-quality products. We have integrated the production at our facility in Gjøvik, ensuring both high quality and continuity in deliveries.

Among these products is the HAVFRONT Loppa 100 – the world’s most compact machine specifically designed for heading and gutting fish onboard vessels. The Loppa 100 is both innovative and user-friendly, optimizing the workflow on coastal fishing vessels from 9 meters, as well as larger sea-going vessels. There are over 60 machines in operation in the Norwegian market today, with solid feedback from users.

The Loppa 100 handles fish ranging from 1 to 12 kilograms and offers a reliable and efficient solution that replaces manual gutting and heading. The machine’s robust design is perfect for vessels looking to improve workflow and reduce manual, labor-intensive tasks.

The machine is highly efficient, requires minimal maintenance, and is built to last – a cost-effective investment for vessels aiming to increase productivity.

HAVFRONT LOPPA 100 – Mustad Autoline (www.mustadautoline.com)

Could this be of interest to you? Please feel free to contact us for more information!