Hauling

After the line has soaked for the predefined time, the hauling of the line starts. The setting process is carried out in reverse order. First 1) the end-buoy and -anchor is hauled on board. 2) Then the groundline and its snoods are gradually hauled

In this process, the catch is detached from the hooks and hooks are automatically separated from the groundline in the hook separator and guided onto the storage magazine (MagPacker).

Finally, the first initial buoy and anchor are hauled on board.

Safety Precautions

The process of setting and hauling gear requires strict attention to safety. Follow these precautions at all times:

-

Stay clear of danger zones. Always remain ahead of anchors, coils of line, and any other equipment that will be thrown overboard.

-

Keep your workspace tidy. Ensure that buoys, floats, and buoy lines are neatly arranged and free of tangles or obstructions.

-

Organize in sequence. Arrange coils, anchors, and other gear in the correct order before setting.

-

Prepare the buoy line carefully. Coil the buoy line neatly, ensuring there are no loops that could catch your foot or snag on other equipment when the line is thrown overboard.

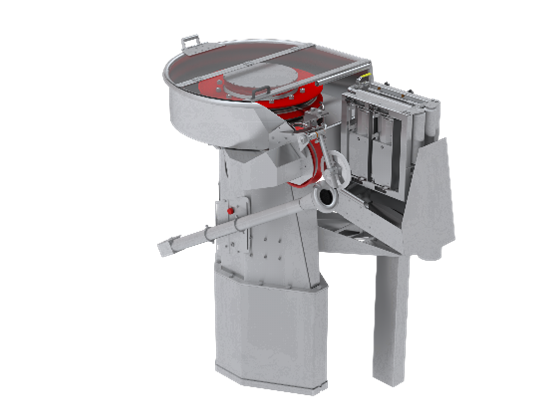

Example of hauling unit; The Mustad Autoline E-line Hauler. More haulers

Example of HookSeparator; The Mustad Autoline E-Line HookSeparator. More HookSeparators

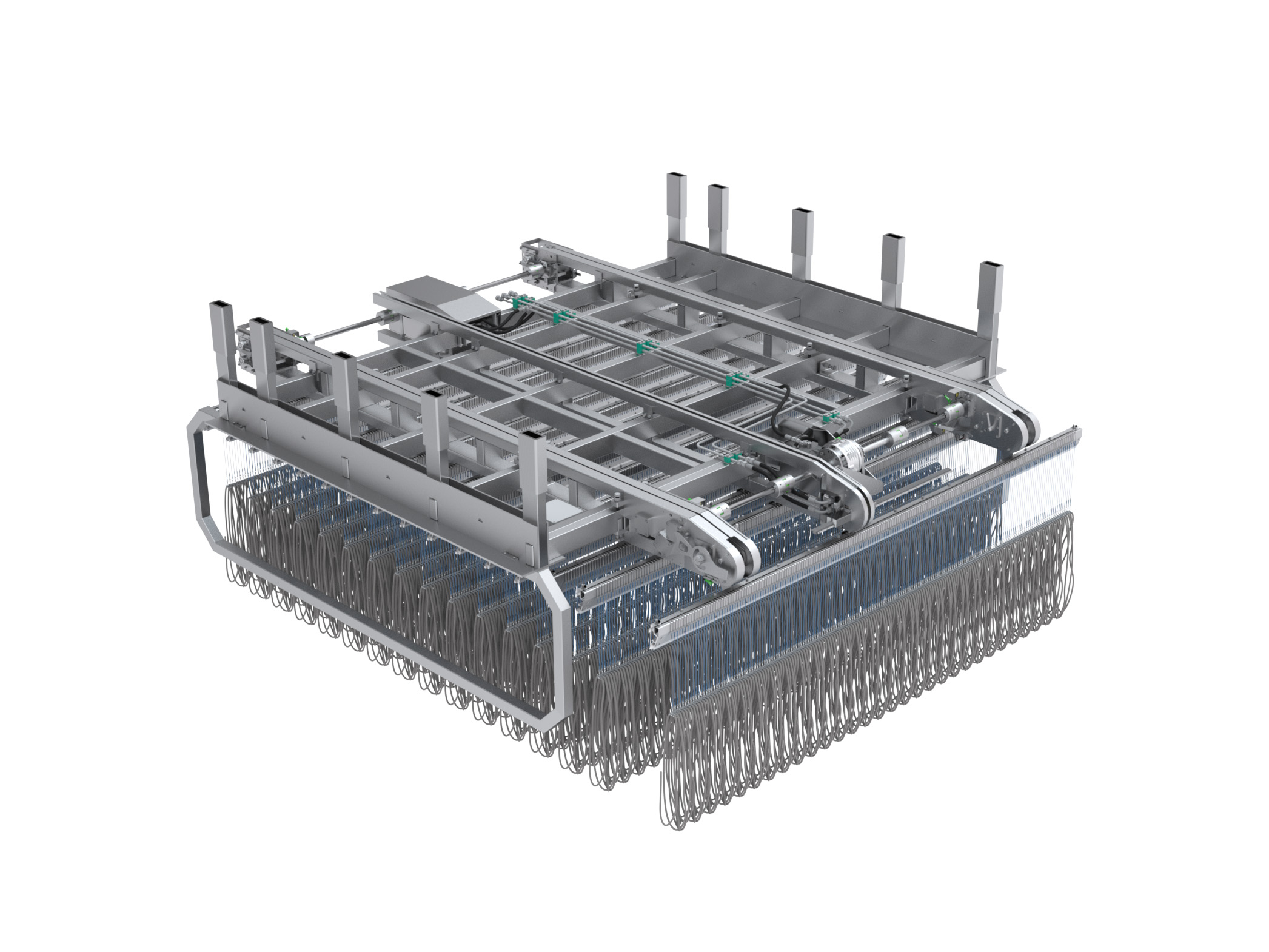

Example of MagPacker storage sytem; The Mustad Autoline E-Line MagPacker sytem. More storage systems

Gaffing and removing hooks

Proper handling during hauling is essential to maintain fish quality and ensure safety on deck. Careful coordination, precise technique, and attention to handling methods help prevent damage to both the catch and the crew, preserving the high value and reputation of line-caught fish.

Bleeding

Proper bleeding is crucial for maintaining the premium quality of line-caught fish. By swiftly and precisely bleeding the fish while it is still fresh, blood is efficiently removed, resulting in cleaner flesh, longer shelf life, and higher market value. Efficient technique and timing are key to ensuring both high-quality products and effective workflow on deck.

Freeing fouled and snagged groundline

Hauling longlines requires steady handling and close coordination with the skipper to avoid tangling or gear loss. Working with the current makes the process smoother, but snagging can still occur. Knowing how to adjust the vessel’s direction, manage line tension, and maintain safe distances is essential to prevent breakage and ensure both crew safety and efficient recovery of the gear.

Handling and storing hooks

Efficient handling and maintenance of snoods are vital for smooth hauling and preparation for the next set. Damaged or twisted snoods must be quickly replaced, hooks reshaped, and tangles cleared to keep the workflow steady. Good coordination along the storage rails ensures that gear moves efficiently, reducing congestion and maintaining both safety and productivity on deck.

Hook handling

Well-maintained hooks are essential for both effective baiting and high catch rates. Sharp, correctly shaped points ensure proper penetration, while accurate offsetting keeps the bait securely in place. Regular inspection and adjustment with a hook corrector help maintain hook integrity, prevent gear failure, and uphold the efficiency and quality standards of longline fishing operations.

Storage hook and lines

The MagPacker system streamlines longline operations by automatically handling and storing hooks and lines, minimizing tangles and manual work. By keeping gear neatly organized and evenly spliced, it enhances both efficiency and safety on board. Proper maintenance—such as repairing or replacing shortened or tangled sections—ensures smooth operation and prolongs the lifespan of the gear.