HAVFRONT LOPPA 100 heading and gutting

Heading and gutting machines

The world’s most compact machine designed for heading and gutting fish onboard fishing vessels, enhancing productivity and reducing the crew’s need for strenuous manual labor.

Key Features

- Type of fish cod, saithe, tusk, ling, haddock etc.

- Capasity 20 fish pr. min

- Fish size 1 - 12 kg

- Operator 1 person

- Pre-treatment throat cutting

Product Information

The HAVFRONT Loppa 100 is the world’s most compact machine specifically designed for heading and gutting fish onboard vessels. This innovative and user-friendly machine enhances the efficiency of fish processing, making it an ideal solution for coastal fishing vessels from 9 meters, as well as larger sea-going vessels. Designed to handle mixed whitefish, the Loppa 100 is a reliable, efficient alternative to manual gutting and heading.

Capable of processing fish weighing between 1 and 12 kilograms the Loppa 100 offers a simple yet robust design, perfect for vessels looking to improve workflow and reduce labor-intensive tasks. The machine allows for quick and precise fish positioning, belly down between centering plates, with the bleed cut aligned over the transverse shaft. The cycle is activated by the user, during which the fish is headed and gutted. There is stepless adjustment for the heading angle and the length of the gut cut.

The HAVFRONT Loppa 100 is highly efficient, low-maintenance, and designed for long-lasting use, making it a cost-effective investment for vessels focused on improving productivity while minimizing manual labor.

HAVFRONT LOPPA 200 heading and gutting

Heading and gutting machines

The Loppa 200 is designed for land-based facilities to improve efficiency and reduce the resource-intensive work of gutting and heading whitefish.

Key Features

- Type of fish cod, saithe, tusk, ling, haddock etc.

- Capasity 20 fish pr. min

- Fish size 1 - 12 kg

- Operator 1 person

- Pre-treatment throat cutting and bleeding

Product Information

HAVFRONT Loppa 200 is one of the worlds smallest machines for heading and gutting of fish.

The HAVFRONT Loppa 200 processes fish weighing between 1 and 12 kg. This machine is straightforward and highly efficient, requiring minimal maintenance. The Loppa 200 is CE marked and includes the necessary modifications for approved use for land-based Norwegian industry.

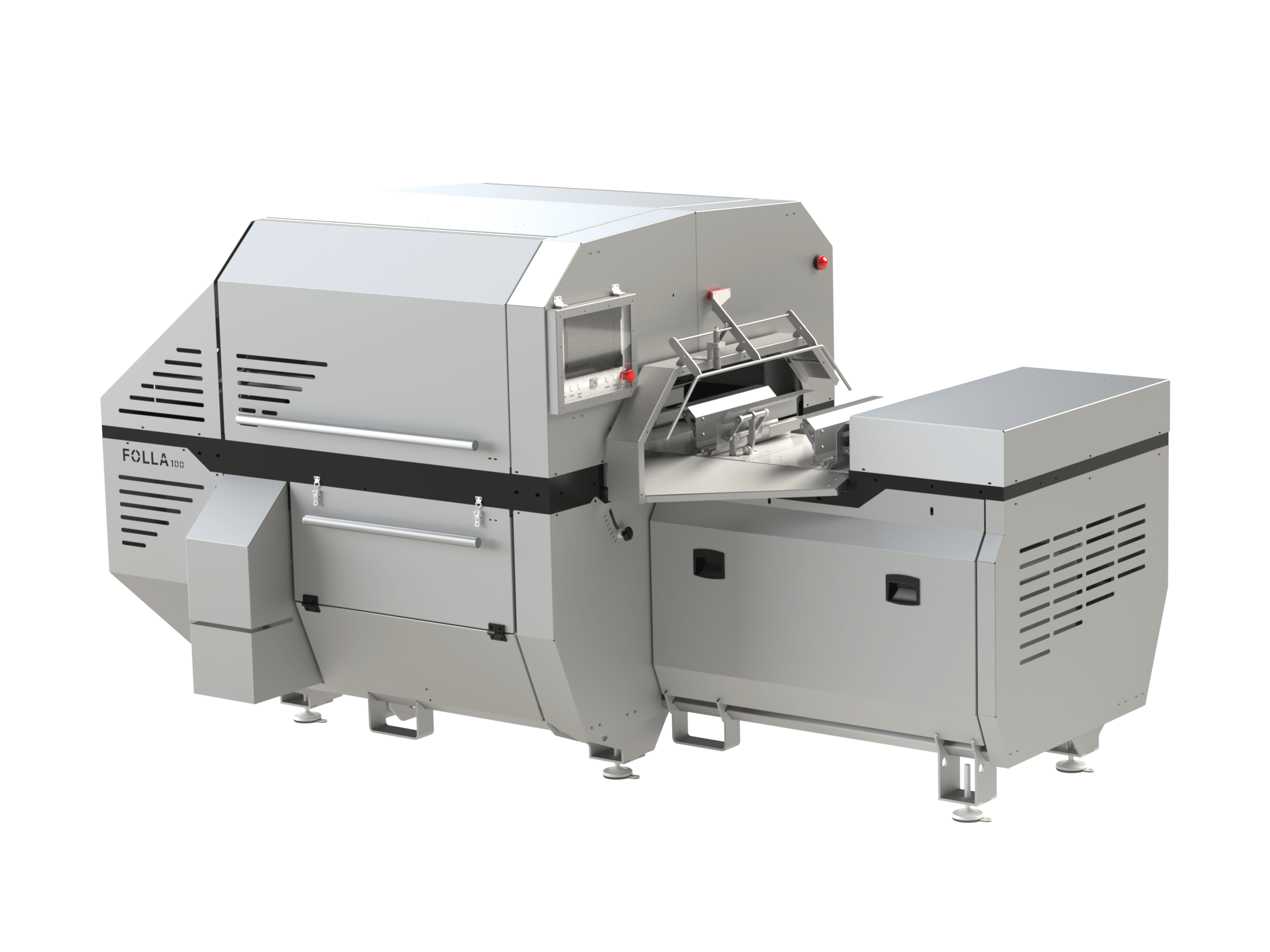

HAVFRONT FOLLA - heading and gutting

Heading and gutting machines

HAVFRONT FOLLA is a fully electric machine designed for precise, gentle, and efficient gutting and heading of whitefish. With advanced technology and high precision, FOLLA ensures optimal raw material utilization, preserving roe and liver intact – adding value to the final product.

The machine reduces the need for heavy manual labor and increases productivity in the production line while delivering consistent, high-quality results. With HAVFRONT FOLLA, you get a reliable, modern solution that optimizes the process and ensures the best possible utilization of raw materials.

Key Features

- Type of fish cod, saithe, tusk, ling, haddock, catfish etc.

- Capasity up to 25 fish pr. min

- Fish size 1 - 25 kg

- Operator 1 person

- Pre-treatment deep throat cutt

Key Information

- Weight 1600 kg

- Power Supply Electric 230V/400V, air pressure 8 bar and water

- Lenght 320 cm

- Width 170 cm

- Height 180 cm

Product Information

HAVFRONT FOLLA is designed for gutting and heading of whitefish, with the option for the operator to activate or deactivate these functions as needed. The fish is pre-treated with a deep throat cut, and the bleeding cut is part of the machine’s reference system. For the best results, the fish should be bled out in cold, running water for at least 20 minutes before further processing.

FOLLA is configured for the specified fish size and production speed, but proportions and quality (season, catch area, etc.) may affect these figures.

The placement and adaptation of the machine to the production line must be carried out by the buyer or personnel chosen by the buyer. We can assist in assessing its placement in the line together with the customer and, if necessary, the line supplier. Our personnel will handle the startup and training of employees as soon as the machine is correctly placed in the gutting line and ready for operation.

Contact us for more information!